Lifting screw jacks are powerful tools for precise and controlled linear motion in various industrial applications. Their ability to efficiently convert rotary motion into lifting or pushing force makes them ideal for tasks requiring accurate positioning. This article explores key strategies to maximize positioning efficiency with lifting screw jacks.

Optimizing Screw Jack Selection:

- Match Capacity to Load: Choosing a screw jack with a capacity exceeding your anticipated load ensures smooth operation and prevents overloading, which can lead to inefficiency and damage.

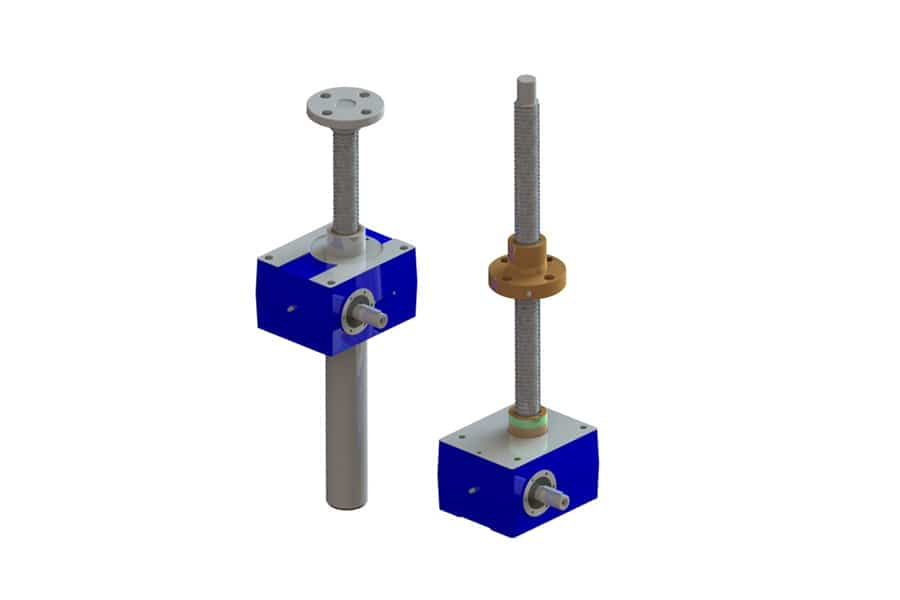

- Select the Right Screw Type:

- Ball Screw Jacks: Offer superior efficiency due to low friction, ideal for high-speed and high-precision positioning applications.

- Machine Screw Jacks: Provide a more cost-effective option and self-locking ability, suitable for moderate-speed tasks where precise positioning is less critical.

- Consider Duty Cycle: Matching the screw jack’s duty cycle to your application’s operational demands ensures it can handle the workload without overheating or premature wear.

Enhancing Positioning Efficiency:

- Drive System Optimization: Utilize high-efficiency motors and gearboxes to minimize energy losses during operation. Consider using variable-speed drives to precisely control lifting or lowering speeds for optimal positioning.

- Minimize Friction: Lubricate screw mechanisms properly to reduce friction between moving parts. Utilize high-quality bearings and seals to minimize energy consumption during operation.

- Environmental Control: Maintain a clean and controlled environment around the screw jack to prevent dust, dirt, or moisture buildup, which can increase friction and hinder efficient movement.

- Positioning Feedback and Control Systems: Integrate sensors and feedback loops into the system to monitor screw jack position and ensure accurate and repeatable movements. Utilize programmable logic controllers (PLCs) to automate positioning tasks for improved efficiency.

For more information on screw jack design and material selection, you can visit MechJacks https://mechjacks.com/en/. MechJacks is a leading manufacturer of high-quality screw jacks, offering a wide range of options to suit various industrial applications.

Additional Tips for Efficiency:

- Minimize Deadweight: Reduce the weight of components attached to the screw jack to minimize the load it needs to move, thereby improving efficiency.

- Proper Maintenance: Regularly inspect and maintain the screw jack according to manufacturer recommendations. This helps to identify and address potential issues early on, preventing inefficiencies and downtime.

By following these strategies, you can maximize the efficiency of your lifting screw jack system and achieve precise positioning within your industrial applications. Remember, consulting with a qualified engineer or screw jack specialist can be beneficial to ensure you select the optimal solution for your specific needs.